Interfab Capability Snapshot

CNC Laser Cutting

Interfab has a high accuracy and high speed CNC laser cutting machine, which has a pallet changer and an automatic sheet feeder to increase production efficiencies and reduce costs. The sheet cutting size is 3050mm x 1500mm cutting up to 10mm plate, often utilised to cut steel, stainless steel, aluminium, copper, brass and other alloys. Do you require sheetmetal CNC Laser Cutting for your job?

CNC Bending / Forming

Interfab has 6 press brakes used for CNC bending or forming. The image on the left shows the larger machines, which can fold upto 2450mm in length, with 2 other CNC machines out of view. The precision sheetmetal work that Interfab manufactures is often measured with a vernier to achieve the precision, tight tolerance requirements that Interfab's customers demand of their high quality products.

Sheetmetal Fabrication

Interfab's sheetmetal fabrication capability includes spot welding, stud welding, Mig & Tig welding. Interfab has several inserting and riveting machines for all sheet metal requirements. With ticketed welders, Interfab can even weld up to 10mm plate, stainless steel, aluminium, pipe, tube, explosion proof boxes, copper, brass and various alloys, depending on what the customer requires.

Stainless Steel Welding

A high portion of Interfab's sheetmetal welding is comprised of stainless steel. With ticketed welders that are highly capable in welding thin gauge sheetmetal to provide a watertight weld seal. The image on the left is a thin gauge stainless steel explosion proof box, welded in high numbers by our highly skilled welders. Can Interfab be of assistance to you for your simple or complex stainless steel welding requirements?

Aluminium Welding

Interfab's highly skilled welders are able to weld thin gauge aluminium less than 2mm thick and upto 10mm plate, as shown in the image on the left. The highly experienced and ticketed welders have the ability to lay down beautiful welds, at least in the eyes of a technical person. Aluminium welding jobs comprise of simple or difficult, thin gauge or thick plate. It really depends on what the customer requirements are.

Powder Coating

Interfab offers a one stop shop where metal parts or jobs are manufactured by Interfab, where the powder coated portion is now completed in-house. More than 50% of Interfab's jobs require powder coating, which is performed by Interfab personnel. In some cases, customers request Interfab to also perform the assembly after powder coating.

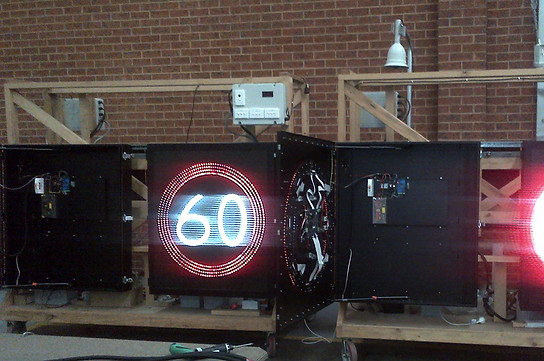

Assembly - Mech & Elec

Interfab offers the ability to also provide complete assembly of mechanical and electrical components in house. This is something that Interfab performs on a regular basis, but ultimately determined by the customer as to whether Interfab completes this task or the customer will.

CNC Punch

Interfab's CNC punch machine is a highly accurate and well maintained machine. The efficiency with CNC punch jobs is having the required tooling to complete jobs faster than a laser and not have to wait for punch tooling to be manufactured. Fortunately, Interfab has over 1,000 punch and forming tools of different sizes and shapes for your sheetmetal requirements. Can Interfab punch your next job?

Laser/Punch Combination

The CNC laser / punch combination machine is a very valuable tool for our customers. It makes many sheetmetal cutting and punching jobs so much more efficient. This Trumpf machine also comes with a Sheetmaster, an automatic sheet feeder, providing further efficiencies. This becomes highly valuable for running jobs at night and on weekend, where it knows when to stop, ready for next day's work.

Grind / Linish Machine

This grinding or linishing machine is very valuable when looking to provide a high quality surface finish. This machine can be adjusted for thickness and set how much to clean off. This is especially important after CNC punching where sheetmetal can be heavily marked on the back face. Aluminium, being a softer material, has the most obvious scarring and is an essential machine within Interfab's offering of high quality product finish.

Plating

As Interfab manufactures a high number of electronic components for different clients, where these materials, whether they be steel, aluminium or stainless steel, may require some form of plating to achieve the desired technical effect. The image on the left shows 4 different metal components that have been plated for different jobs.

Screen Printing

Interfab can also offer screen printing for customer jobs. Sometimes the printing requirements include coloured laser etching (which involves laser etching then powder coating the laser etched cavity); stencil printing (which looks very similar to screen printing) and of course placing decals (stickers) on finished products. These tasks are managed by Interfab through its regular suppliers.

Tiny Precision Laser Parts

The CNC laser cutter and the CNC laser / punch combination machines are checked daily to ensure their cutting precision is 30 microns (0.030 mm) or better. You can see in the small components on the left the precision laser cutting required to manufacture the various parts. Can Interfab assist you with any precision parts that need laser cutting to our mutual benefit?

Large Projects

Interfab has the facility and capability to take on large projects as well as manufacture small components. The image on the left shows numerous ticket vending machines for the transport authority, in this case made of stainless steel. Over a fifty units were manufactured for this project and delivered to our customer's sites.

Defence Projects

Over the years Interfab has manufactured numerous parts and sheetmetal enclosures for Australia's Navy, Army and Air Force. Interfab's precision sheetmetal manufacturing services have been utilised to deliver quality components, often for electronics, power and communications hardware. This service has been for Defence Prime Contractors from ship builds to smaller projects, where Interfab is always a Tier 2 or 3 supplier.

Precision Sheet Metal

Interfab has the skilled personnel and machinery to manufacture very precise and intricate metal components and in various metals. The precision work in the image on the left shows the mating tabs along the leading edge and around the bend. There are many intricate jobs that Interfab has manufactured and kept samples of over the years, although it is not always easy to demonstrate tight tolerances into visual translation.

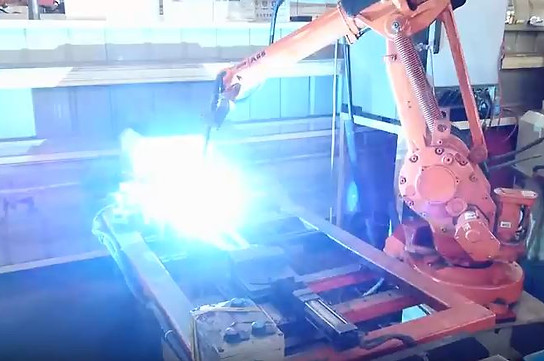

Robotic MIG & TIG Welding

Welding, along with all other manufacturing processes, has been at the centre of a relentless pursuit of improved quality, better lead times, increased capacity via expansion or innovation and automation through technology. Interfab has invested in state of the art robotic MIG and TIG welding unit. With two separate automated welding cells, Interfab has the capability to weld materials with efficient cycle times and with consistent accuracy.

CNC Punch Tooling List

Interfab has a large range of CNC punch tooling that is often requested by designers and engineers to utilise within their sheet metal designs as punching is faster and more efficient than laser cutting. If there are requirements that are not on the tool list below, then all is not lost as Interfab can utilise the CNC Laser/Punch Combination to only laser cut the shape(s) where punch tooling is not available. Click on button below for punch tooling list.